In the ever-evolving landscape of material handling, the Rubber Belt Traction Machine stands out as a transformative innovation that enhances efficiency and productivity across various industries. According to a report by Grand View Research, the global material handling equipment market is expected to reach USD 250 billion by 2026, driven by the need for advanced solutions that streamline operations.

The Rubber Belt Traction Machine plays a crucial role in this growth by facilitating the seamless movement of goods and materials, minimizing manual labor, and reducing operational costs. Its unique design and reliability allow for greater load capacity and speed, making it an integral component in sectors such as manufacturing, logistics, and construction. As industries seek to optimize their processes, the Rubber Belt Traction Machine not only meets the current demands but also paves the way for future innovations in material handling techniques.

The Rubber Belt Traction Machine plays a crucial role in this growth by facilitating the seamless movement of goods and materials, minimizing manual labor, and reducing operational costs. Its unique design and reliability allow for greater load capacity and speed, making it an integral component in sectors such as manufacturing, logistics, and construction. As industries seek to optimize their processes, the Rubber Belt Traction Machine not only meets the current demands but also paves the way for future innovations in material handling techniques.

Rubber belt traction machines represent a significant advancement in material handling techniques, streamlining the transportation of goods across various industries. At their core, these machines utilize a flexible rubber belt that can navigate different terrains and surfaces, ensuring that materials are moved efficiently and safely. Their design allows for a smooth transfer of items, minimizing the risk of damage during transit, which is crucial in sectors such as manufacturing and logistics.

The innovation behind rubber belt traction machines lies in their adaptability and ease of use. Unlike traditional methods that may rely on rigid equipment or manual labor, these machines can adjust to various loads and conditions, making them versatile for any operation. Additionally, the frictionless movement of the rubber belt reduces wear on both the machine and the materials being transported, ultimately contributing to lower maintenance costs and enhanced productivity. As industries continue to search for more efficient material handling solutions, rubber belt traction machines are poised to play a pivotal role in advancing operational efficiency and safety standards.

Rubber belt traction machines represent a significant advancement in material handling techniques, offering several key advantages over traditional equipment. One primary benefit is their ability to provide consistent and reliable traction, which is essential for transporting materials efficiently across various surfaces. Unlike conventional systems that may struggle with slippage or uneven load distribution, rubber belts are designed to enhance friction, ensuring smoother movements and minimizing wear on both the machine and the materials being handled.

Another notable advantage is the versatility of rubber belt traction machines. They can be adapted for different applications, from heavy construction materials to delicate goods. This adaptability allows businesses to optimize their operations and reduce downtime associated with switching equipment. Additionally, the inherent flexibility of rubber belts enables them to navigate complex pathways and tight spaces more effectively than traditional rigid systems, resulting in improved overall workflow and productivity.

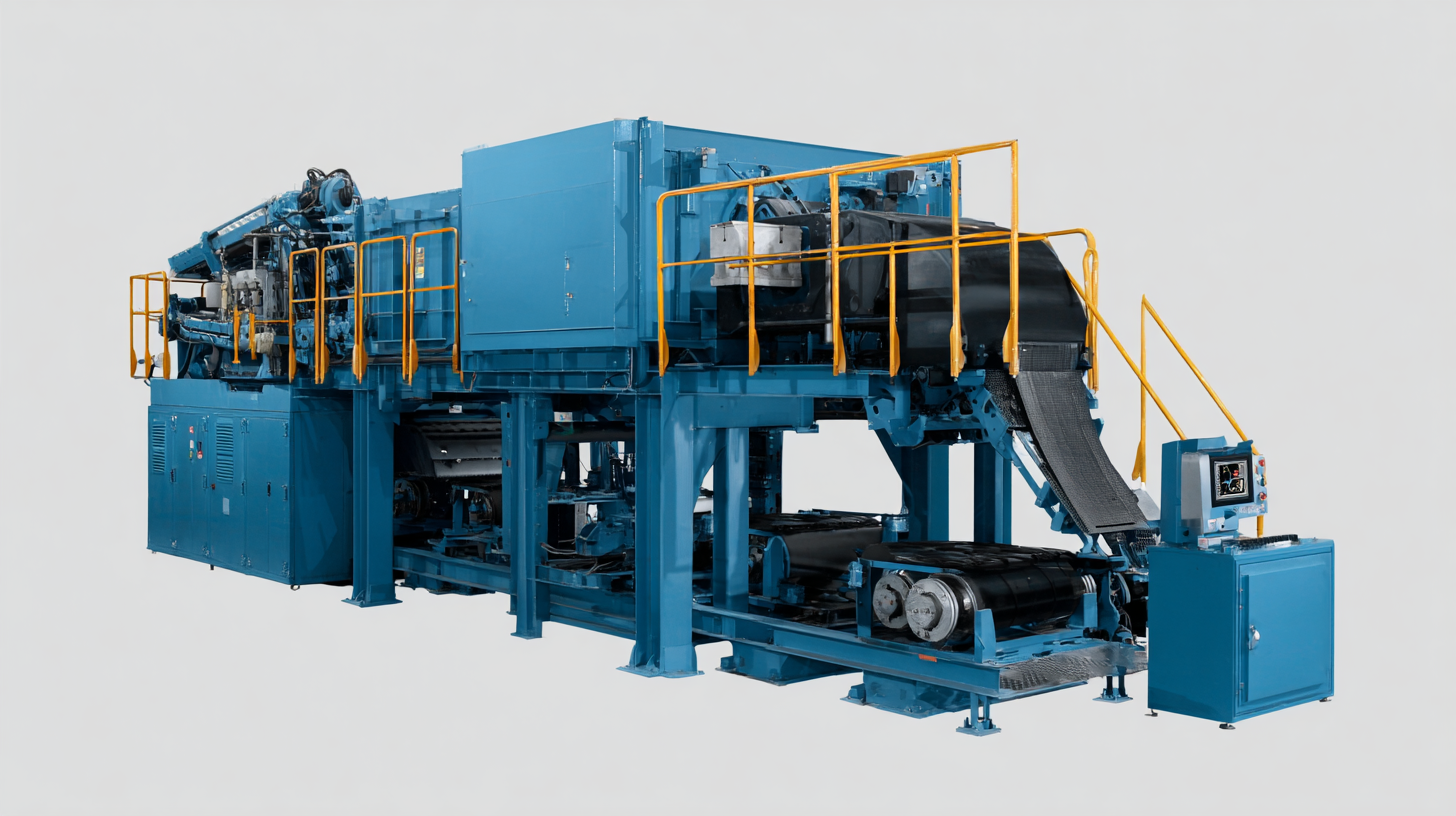

Rubber Belt Traction Machines represent a significant advancement in material handling technology, boasting several innovative features that enhance operational performance. One of the key enhancements is the incorporation of advanced materials that improve durability and efficiency.

These machines utilize high-quality rubber belts designed to withstand harsh industrial environments, improving longevity and reducing the frequency of replacements. This innovation is crucial as the demand for effective material handling solutions continues to surge in various sectors marked by rapid industrialization.

These machines utilize high-quality rubber belts designed to withstand harsh industrial environments, improving longevity and reducing the frequency of replacements. This innovation is crucial as the demand for effective material handling solutions continues to surge in various sectors marked by rapid industrialization.

Moreover, modern Rubber Belt Traction Machines are equipped with intelligent monitoring systems that provide real-time data on performance, allowing for proactive maintenance and reducing downtime. The integration of these technologies not only boosts the reliability of conveyor systems but also elevates productivity levels significantly. Enhanced grip and traction from the rubber belts ensure smoother operations, even when handling bulky or sticky materials. As industries seek to optimize their processes, the innovative features of Rubber Belt Traction Machines position them as essential tools for achieving greater efficiency in material handling.

Rubber belt traction machines are transforming material handling across various industries, offering innovative solutions to enhance operational efficiency and safety. Their design integrates advanced technology that provides excellent grip and traction, making them particularly effective in environments like construction, agriculture, and mining. These machines can efficiently transport heavy materials, reducing the risk of manual handling injuries and increasing productivity.

In sectors where workplace safety is paramount, the integration of rubber belt traction machines is becoming essential. With the rise of wearable technologies and connected-worker solutions, these machines complement efforts to enhance worker health and safety. By automating material transport, companies can minimize the physical strain on workers while streamlining processes. The efficiency of rubber belt systems also aligns with the current trends in smart manufacturing, where real-time data and advanced mechatronic systems optimize operations, ensuring that industries are better equipped to meet modern demands and challenges.

| Industry | Application | Benefits | Key Features |

|---|---|---|---|

| Construction | Transporting materials like gravel and sand | Increased efficiency and reduced manpower | Durable rubber belts, high load capacity |

| Mining | Transporting ores and minerals | Reduced downtime and operational costs | High traction surface, weather-resistant |

| Agriculture | Moving bulk grains and fertilizers | Enhanced product handling and reduced spillage | Flexible design, adjustable speed |

| Food Processing | Conveying packaged goods | Improved hygiene and easier cleaning | Food-grade materials, anti-static options |

| Logistics | Sorting and distributing packages | Increased throughput and accuracy | Modular design, easy to integrate with systems |

Rubber belt traction machines are revolutionizing material handling by providing superior grip and durability, thus enhancing efficiency across various industries. According to a report by Research and Markets, the global material handling equipment market is expected to reach $263.7 billion by 2026, growing at a CAGR of 6.3%. This growth can be attributed to innovations like rubber belt traction machines, which increase the speed and safety of transporting materials in warehouses and manufacturing plants.

To maximize efficiency with rubber belt traction machines, it’s essential to ensure proper maintenance and timely replacement of worn belts. The American National Standards Institute (ANSI) recommends regular inspections to mitigate the risk of slippage and operational downtime. Additionally, optimizing load distribution can significantly enhance performance; a study by the Material Handling Industry of America highlights that correctly distributing loads can lead to a 20% increase in operational productivity. Implementing these strategies will not only improve overall efficiency but also extend the lifespan of the equipment, making it a worthwhile investment for any operation.