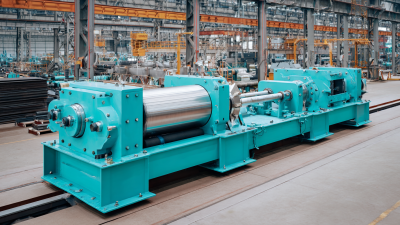

In today's fast-paced industrial landscape, businesses are continually seeking innovative tools to enhance productivity and efficiency. One such tool that has gained prominence is the Rubber Belt Rewinder Machine. This powerful equipment plays a crucial role in the processing and handling of rubber belts, ensuring that they are efficiently rewound for storage or transport. By incorporating a Rubber Belt Rewinder Machine into your operation, you can streamline processes, save on labor costs, and improve overall workflow.

The benefits of using a Rubber Belt Rewinder Machine extend beyond mere convenience. This machine not only optimizes the physical handling of rubber materials but also minimizes waste and damage, promoting sustainability in manufacturing practices. Moreover, it enhances the safety of workers by reducing the manual handling of heavy materials, which can lead to injuries. As industries continue to evolve, understanding and leveraging the advantages of a Rubber Belt Rewinder Machine can set a business apart from its competitors, making it a valuable investment for any forward-thinking enterprise.

Rubber belt rewinders have revolutionized material handling processes across various industries. One of the most significant benefits is the enhanced efficiency that these machines bring to operations. By automating the winding and unwinding of rubber belts, businesses can significantly reduce the time spent on manual labor. This not only accelerates the overall workflow but also minimizes the risk of human error, ensuring that materials are handled with precision. As a result, companies experience faster turnaround times, which is critical in maintaining a competitive edge in today’s fast-paced market.

Additionally, rubber belt rewinders contribute to improved safety in the workplace. By mechanizing the process, the potential for injuries associated with handling heavy belts manually is substantially lowered. Workers can focus more on their primary tasks without the burden of performing repetitive and physically demanding movements. Moreover, these machines often include safety features that protect operators, adding an extra layer of security to material handling operations. Ultimately, the implementation of rubber belt rewinders not only streamlines processes but also fosters a safer working environment, making them an invaluable investment for businesses looking to optimize their material handling systems.

In today's competitive business landscape, cost efficiency is paramount, and utilizing a rubber belt rewinder machine can be a game-changer. By automating the rewinding process, businesses can significantly reduce labor costs. According to a report by the Manufacturing Institute, companies that automate repetitive tasks can see labor cost reductions of up to 30%. This not only frees up employees for higher-value tasks but also minimizes overtime expenditures that can quickly inflate operational budgets.

Moreover, the maintenance implications of employing a rubber belt rewinder machine are noteworthy. A study by The Industrial & Manufacturing Industry Association indicates that automated systems typically require less maintenance than manual processes, potentially reducing maintenance costs by as much as 25%. The reduced wear and tear on equipment, combined with improved efficiency, results in fewer breakdowns and less downtime. This shift not only enhances productivity but also translates to substantial financial savings, allowing businesses to allocate resources more effectively and focus on growth and innovation.

The use of a rubber belt rewinder machine significantly enhances workplace safety, addressing common hazards associated with manual handling of heavy materials. According to the Occupational Safety and Health Administration (OSHA), more than 300,000 musculoskeletal disorders occur each year in the workplace, often due to improper lifting techniques and repetitive motions. By automating the process of rewinding rubber belts, businesses can mitigate these risks and protect employees from potential injuries. The rewinder machine not only reduces the physical strain on workers but also minimizes the likelihood of accidents resulting from improperly coiled belts or workplace clutter.

Furthermore, studies show that effective equipment aids in maintaining an organized work environment, which is crucial for preventing slips and trips—two of the leading causes of workplace injuries. In fact, the National Safety Council reports that such incidents account for nearly 25% of all workplace injuries. By implementing a rubber belt rewinder, companies can maintain tidy workspaces, as the machine efficiently handles the winding process, leaving no loose materials that could pose risks. Additionally, an organized setup promotes better workflow and productivity, leading to a more engaged and safer workforce. As businesses increasingly prioritize safety measures, investing in automated solutions like rubber belt rewinders becomes essential not only for employee well-being but also for improving overall operational efficiency.

Rubber belt rewinder machines are becoming increasingly invaluable across various industries due to their versatility and efficiency. In manufacturing, these machines facilitate the swift reeling of rubber belts, ensuring that production lines maintain their pace without unnecessary downtime. According to a report by MarketsandMarkets, the global conveyor system market is projected to reach USD 7.5 billion by 2026, highlighting the growing demand for products that streamline production processes and enhance operational functionality. By incorporating rubber belt rewinders, manufacturers can optimize their workflows, reducing the time and labor costs associated with manual belt handling.

In the logistics and distribution sector, rubber belt rewinder machines play a crucial role in managing inventory and improving shipment efficiency. A study published by Research and Markets indicates that the logistics industry is expected to grow at a CAGR of 4.5% between 2021 and 2026. These machines aid in the organization of materials, allowing for quick access and minimal handling—an essential feature for businesses aiming to boost their competitiveness. Furthermore, the ability of rubber belt rewinders to accommodate various belt sizes enhances their adaptability, making them suitable for different cargo types, whether light or heavy. By leveraging this technology, companies can effectively respond to dynamic market demands, ultimately leading to improved service delivery and customer satisfaction.

The use of a rubber belt rewinder machine significantly simplifies operations in various industries. This equipment allows businesses to efficiently manage their materials, focusing on both ease of use and automation options. According to a recent industry report by the Manufacturing Institute, companies that have adopted automated systems experience a 30% increase in productivity. With intuitive controls and programmable settings, staff can quickly learn how to operate these machines, reducing the time needed for training.

Automation not only streamlines the rewinding process but also enhances precision and consistency. The International Journal of Advanced Manufacturing Technology highlights that automated machines can help reduce error rates by up to 50% compared to manual methods. Moreover, integrating these machines into a production line can lead to safer working environments as they often incorporate features like automatic shut-off and emergency stop functions.

**Tips for Maximizing Your Rubber Belt Rewinder:**

- Ensure regular maintenance checks to prevent downtime and keep the machine running smoothly.

- Train your staff on the latest operational techniques to leverage all available automation features.

- Continuous monitoring of output can help identify any inefficiencies, allowing for timely adjustments and improved productivity.