The leather industry is undergoing a significant transformation, driven by the need for sustainable practices and increased efficiency in production. As highlighted in the latest market research reports, the global leather goods market is projected to reach $430 billion by 2027, with a notable rise in demand for innovative technologies that enhance production speed and precision. One such technological marvel is the Belt Cutting Machine, which plays a pivotal role in revolutionizing how leather is processed.

These machines not only streamline the cutting process but also reduce waste, contributing to more environmentally friendly manufacturing practices. Industry case studies reveal that manufacturers utilizing advanced belt cutting machines have reported up to a 30% increase in productivity while minimizing costs. As we delve into insights and real-world applications, it's clear that the future of leather production is intricately linked to the adoption of cutting-edge tools like the Belt Cutting Machine.

These machines not only streamline the cutting process but also reduce waste, contributing to more environmentally friendly manufacturing practices. Industry case studies reveal that manufacturers utilizing advanced belt cutting machines have reported up to a 30% increase in productivity while minimizing costs. As we delve into insights and real-world applications, it's clear that the future of leather production is intricately linked to the adoption of cutting-edge tools like the Belt Cutting Machine.

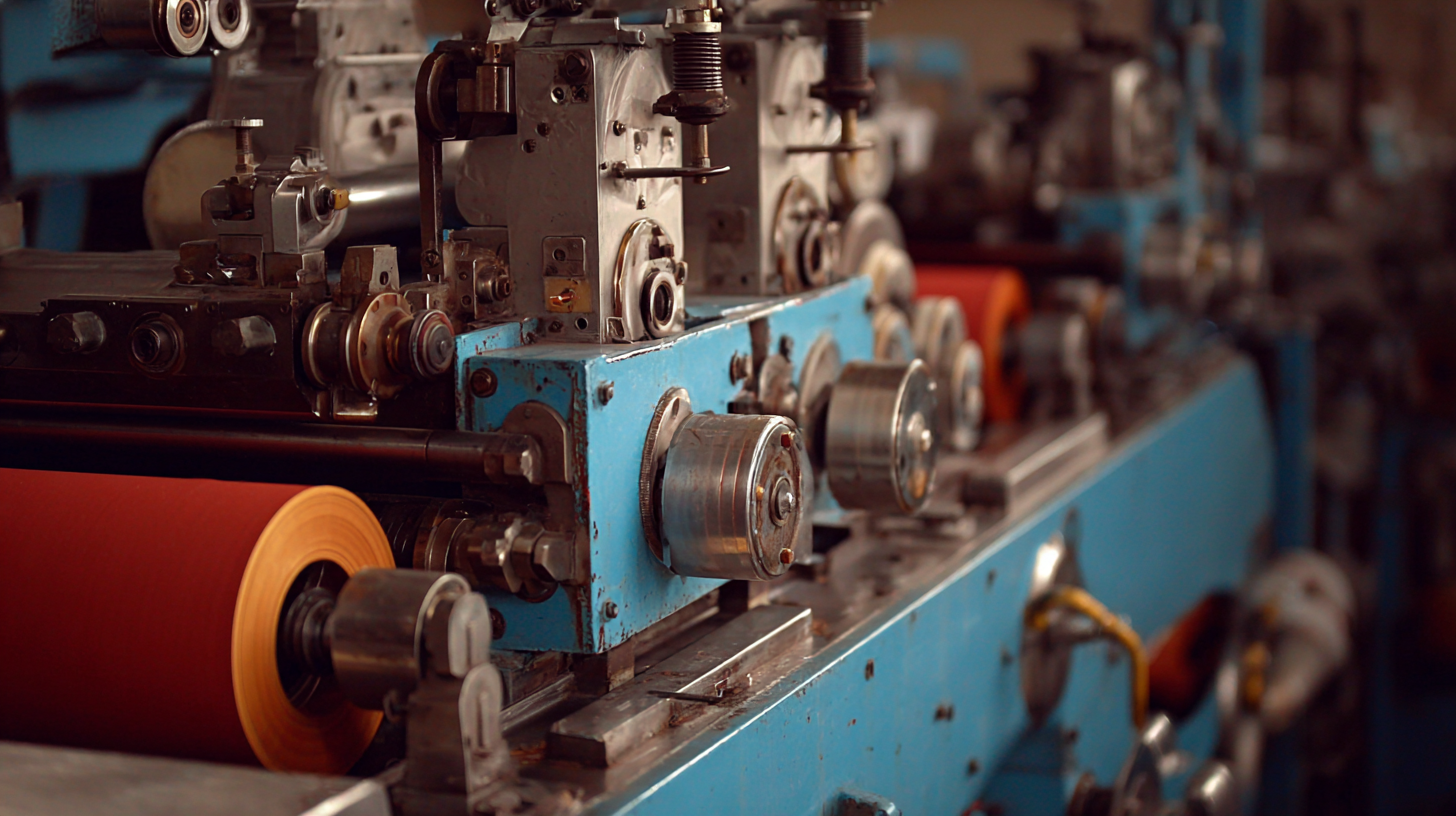

The evolution of belt cutting machines has transformed the leather production industry, pushing boundaries in efficiency and precision. Initially, leather cutting was a labor-intensive process, requiring skilled artisans to manually carve patterns and designs. This method, while showcasing remarkable craftsmanship, often fell short in terms of consistency and productivity. The introduction of belt cutting machines revolutionized this landscape, significantly reducing human error and enhancing the overall quality of the products.

As technology advanced, the sophistication of these machines increased, now featuring computer numerical control (CNC) capabilities that allow for intricate designs to be cut with exceptional accuracy. This shift not only streamlines the production process but also allows for greater customization, catering to the evolving demands of consumers who seek unique and personalized leather goods. Case studies highlighting manufacturers who adopted these machines reveal a substantial increase in output, cost-effectiveness, and a reduction in material waste, showcasing how the modernization of cutting techniques is fostering sustainability within the industry.

This chart illustrates the evolution of belt cutting machines in leather production, highlighting the increase in production efficiency from manual to fully automatic machines. As technology advances, the efficiency of leather production significantly increases, enabling manufacturers to meet higher demands.

When considering a high-quality belt cutting machine for leather production, several key features stand out as essential for efficiency and precision. Firstly, the cutting accuracy and speed are paramount. A good machine should be capable of delivering precise cuts at a rapid pace, ensuring minimal waste of materials and enhancing overall production efficiency. Advanced laser technology or precision blades can significantly improve the accuracy of cuts, allowing for intricate designs without compromising quality.

Another critical feature to look for is automation and user-friendliness. A machine equipped with programmable settings can streamline the cutting process, enabling operators to execute multiple designs with ease. Additionally, intuitive controls and interface will reduce the learning curve for new users, allowing businesses to maximize their productivity without extensive training. Lastly, durability and maintenance requirements should not be overlooked; investing in a robust machine that is easy to maintain will save both time and costs in the long run, ensuring consistent performance in a demanding production environment.

In recent years, the leather production industry has seen a significant transformation, driven by technological advancements in cutting machine design. Case studies highlight how innovators are leveraging the latest belt cutting machines to enhance efficiency and precision in leather processing. According to a report from Smithers Pira, the global leather goods market is projected to reach $438 billion by 2025, emphasizing the need for cutting-edge production techniques to meet growing demand.

One notable success story involves a company that integrated a state-of-the-art belt cutting machine, leading to a 30% reduction in material waste. By utilizing advanced software for pattern optimization, this company not only improved its output but also enhanced product quality, positioning itself as a leader in sustainable practices within the industry. Similarly, another innovator reported a 25% increase in production speed, highlighting how the integration of automation in leather cutting processes can significantly impact profitability and market responsiveness.

These case studies serve as compelling evidence of how the right technological investments can revolutionize leather production, making it more efficient and environmentally responsible.

The modernization of belt cutting processes in leather production can be significantly influenced by the choice between manual and automated systems. A comparative analysis reveals that while manual cutting offers flexibility and minimal setup costs, it often results in inconsistencies and inefficiencies. For instance, reports show that manual processes can lead to a material wastage rate of up to 20%, while automated systems can reduce this to as low as 5%. This efficiency, coupled with the ability to maintain high precision, positions automation as a compelling choice for manufacturers aiming for scalability and quality.

In a case study involving a leading leather goods manufacturer, the shift to an automated belt cutting machine resulted in a 30% reduction in production time and a ten-fold increase in daily output compared to manual methods. Furthermore, the integration of smart technologies allows for real-time monitoring and adjustments, ensuring that the production line adapts quickly to changing demands. As automation continues to evolve, it is predicted that the global market for automated belt cutting machines will see a CAGR of over 15% in the next five years, highlighting the trend towards mechanization in the leather industry.

The leather production industry is undergoing a significant transformation, driven by advancements in technology and a growing focus on sustainability. As the demand for eco-friendly materials increases, innovations in synthetic biology are paving the way for more sustainable leather alternatives. For instance, the use of bio-synthetic techniques allows for the fermentation of glucose and other low-cost carbon sources to produce materials that can mimic traditional leather while mitigating environmental impact.

The leather production industry is undergoing a significant transformation, driven by advancements in technology and a growing focus on sustainability. As the demand for eco-friendly materials increases, innovations in synthetic biology are paving the way for more sustainable leather alternatives. For instance, the use of bio-synthetic techniques allows for the fermentation of glucose and other low-cost carbon sources to produce materials that can mimic traditional leather while mitigating environmental impact.

Data suggests that the global sustainable leather market is projected to reach $24.6 billion by 2027, with a compound annual growth rate (CAGR) of 9.1% from 2020. This shift is not only about the material but also about the processes involved in production. Companies are now exploring methods such as bio-based and recycled materials, which contribute to reduced carbon footprints and lower resource consumption. Reports emphasize the importance of embracing these innovations to ensure that leather production aligns with future consumer expectations around sustainability and ethics.

As the industry moves forward, it is imperative that manufacturers invest in technologies that support environmentally friendly practices. This includes adopting advanced cutting machines designed for efficiency and waste reduction, ensuring that the production process is as sustainable as the materials used. By focusing on these trends and integrating new technologies, the leather industry can revolutionize its operations while meeting the demands of a more conscious consumer base.