In the rapidly evolving landscape of modern manufacturing, the significance of efficient cutting tools cannot be overstated, particularly when it comes to the Belt Cutting Machine. According to a report by Market Research Future, the global machine cutting tools market is projected to reach approximately $220 billion by 2025, highlighting a surge in demand for cutting technologies that enhance productivity and precision. As manufacturers strive to optimize processes and reduce waste, exploring innovative alternatives for Belt Cutting Machines becomes paramount. These alternatives not only promise increased operational efficiency but also integrate advanced technologies such as automation and IoT, accommodating the growing need for smart manufacturing solutions. By embracing these innovations, companies can navigate the challenges of a competitive marketplace while improving their bottom line and sustainability efforts.

In the realm of modern manufacturing, the push for efficiency and precision has led to significant innovations in belt cutting technologies. According to a report by *MarketsandMarkets*, the global market for advanced cutting tools is projected to reach $17 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2% from 2021. This surge is primarily driven by the integration of automation and smart technologies, which are re-defining the traditional belt cutting processes.

Key innovations to consider include laser cutting and robotic-assisted machining, which offer unparalleled accuracy and speed. Laser cutting systems, for instance, can reduce material waste by as much as 30% while providing intricate cutting capabilities that exceed those of manual or traditional methods. Additionally, the adoption of Industry 4.0 concepts enhances operational efficiencies, enabling manufacturers to closely monitor and adjust processes in real-time. A survey by *Statista* indicates that 45% of manufacturers are actively investing in smart technologies, demonstrating a clear trend toward modernization in production lines. These advancements signal a transformative shift in how belt cutting machines can operate within the landscape of advanced manufacturing.

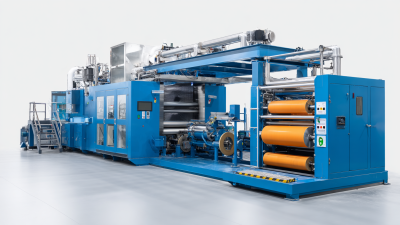

In the realm of modern manufacturing, the comparison between traditional and modern belt cutting machines underscores the pivotal shift in technology and efficiency. Traditional belt cutting machines contribute to a significant portion of production lines, often relying on manual settings and mechanical parts. According to a report by Grand View Research, the traditional cutting machine market was valued at approximately $2.3 billion in 2022, reflecting a stable but slowly declining growth rate as manufacturers seek more efficient solutions.

Conversely, modern belt cutting machines, integrating advanced technologies such as automation and CNC (Computer Numerical Control), are revolutionizing the industry. The same report predicts that the market for automated and high-precision cutting machines could grow to reach over $4.5 billion by 2030, driven by the rising demand for productivity and precision. These innovations not only reduce labor costs but also enhance material utilization, leading to less waste—an essential factor in contemporary ecological considerations. The move towards these modern solutions highlights the industry's commitment to embracing technological advancements for a more sustainable and efficient future.

When exploring innovative alternatives for belt cutting machines in modern manufacturing, it's crucial to focus on the essential features that define next-generation belt cutting equipment. One of the primary features to consider is precision cutting technology. Advanced machines leverage high-resolution sensors and cutting-edge CNC systems to ensure that each cut is not only accurate but also reproducible, minimizing waste and maximizing material efficiency. Such precision is vital for industries where tolerances are critical, enabling manufacturers to enhance overall product quality.

Another important feature is the integration of smart technology, which includes IoT connectivity and data analytics capabilities. This technology allows manufacturers to monitor machine performance in real-time, optimizing the cutting processes based on live data insights. Moreover, machines equipped with automated maintenance alerts can significantly reduce downtime, providing users with the ability to plan maintenance activities proactively. The combination of precision cutting and smart capabilities positions next-generation belt cutting machines as invaluable tools in the competitive landscape of modern manufacturing.

As modern manufacturing continues to evolve, organizations are increasingly evaluating the cost-benefit ratio of innovative solutions such as advanced belt cutting machines. According to a recent industry report, investments in automation and digital technologies can yield a return on investment (ROI) of up to 300% over a five-year period, significantly outpacing traditional manufacturing methods. This strong ROI highlights the importance of not merely cutting costs but strategically reallocating resources towards innovative technologies that enhance productivity and efficiency.

In the face of economic uncertainties, businesses often consider cost-saving measures. However, research indicates that marketing investments during challenging times can bolster resilience, facilitating a robust growth trajectory once conditions improve. For example, firms that maintain or increase their marketing spend during downturns can recover faster, with studies showing a correlation between sustained marketing efforts and revenue growth of up to 30% in subsequent years. Thus, investing in innovative belt cutting solutions not only modernizes operations but also aligns well with broader strategies to enhance market presence and operational flexibility, transforming potential cost-cutting into a strategic improvement in competitiveness.

In the evolving landscape of modern manufacturing, sustainability and efficiency are becoming increasingly pivotal. Amid the pressing need to reduce carbon footprints, sectors like cement manufacturing in India present significant avenues for enhanced efficiency through renewable energy integration. According to industry experts, adopting advanced manufacturing technologies can lead to a substantial reduction in carbon intensity, thus underscoring the essential role of sustainability in business operations.

Furthermore, the shift towards a green economy is evident in countries like China, where substantial investments in renewable energy and sustainable infrastructure are paving the way for a future that prioritizes environmental responsibility. Innovations in manufacturing processes, such as the development of advanced lithium-ion battery manufacturing equipment, highlight the importance of efficiency, especially as industries face challenges in production stages like electrode preparation and assembly. As organizations strive for digital transformation, the integration of cutting-edge technologies can help facilitate a balance between economic viability and environmental stewardship, ultimately shaping a greener future for manufacturing.

| Cutting Technology | Efficiency Rating (%) | Sustainability Score (1-10) | Material Compatibility | Projected Cost ($) |

|---|---|---|---|---|

| Laser Cutting | 90 | 8 | Fabric, Rubber | 15,000 |

| Water Jet Cutting | 85 | 9 | Textiles, Composites | 20,000 |

| Ultrasonic Cutting | 80 | 7 | Foams, Plastics | 12,000 |

| Die Cutting | 75 | 6 | Cardboard, Paper | 8,000 |

| Knife Cutting | 70 | 5 | Leather, Fabric | 10,000 |