Choosing the right Rubber Belt Rewinder Machine can significantly impact your production efficiency. Industry expert John Smith emphasizes, "Selecting the best machine is crucial for optimal performance." His experience in manufacturing highlights the importance of understanding specific needs.

When considering a Rubber Belt Rewinder Machine, you should evaluate various factors. The machine's capacity matters. Think about the types of belts you'll rewind. Some machines handle thicker belts better than others. Operational ease is also key. A complicated interface can slow down productivity.

Additionally, don’t overlook maintenance needs. A reliable machine should require minimal downtime. Yet, some users report unexpected malfunctions with certain models. It's crucial to ask other buyers about their experiences. Thus, your choice must balance quality, functionality, and budget constraints.

Rubber belt rewinder machines are essential in various industries. They help manage rubber belts efficiently. This helps in minimizing waste and improving overall productivity. Understanding how these machines work is crucial for anyone involved in production lines. According to industry reports, proper usage can increase efficiency by up to 30%.

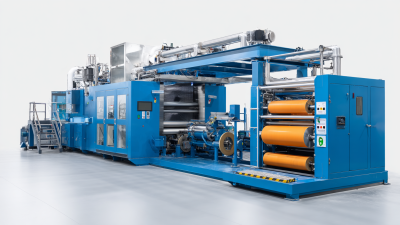

The design of a rubber belt rewinder machine is important. Key features should include adjustable tension and speed controls. These help in handling different rubber materials. Research indicates that machines with user-friendly interfaces reduce errors by 15%. However, some machines may lack these critical features and lead to complications. This can affect the quality of the final product.

Maintenance is another significant aspect. Regular checks can prevent breakdowns that disrupt production. A study revealed that 20% of production downtime is due to machine failure. Investing time in maintenance can save costs and delays in the long run. Nonetheless, many operators tend to overlook this aspect, exposing themselves to potential losses.

Choosing the right rubber belt rewinder machine can be overwhelming. Focus on key features that enhance usability. A sturdy frame is essential for durability. Look for a machine that can easily handle various belt sizes. Adjustable tension controls are also crucial, allowing for precise winding.

The rewinding speed matters significantly. Some machines operate too slowly, causing delays. Others might be too fast, risking damage to the rubber. Check for user-friendly controls. Intuitive operation helps minimize errors and keeps production flowing smoothly. Consider safety features. Emergency stop buttons and protective shields should be standard.

Maintenance is another aspect worth considering. Machines requiring frequent repairs can lead to downtime. Some models offer self-lubricating systems. This feature reduces the need for constant care. Don't ignore the power source; some machines may be more energy-efficient than others. Ultimately, prioritize the features that align with your production needs.

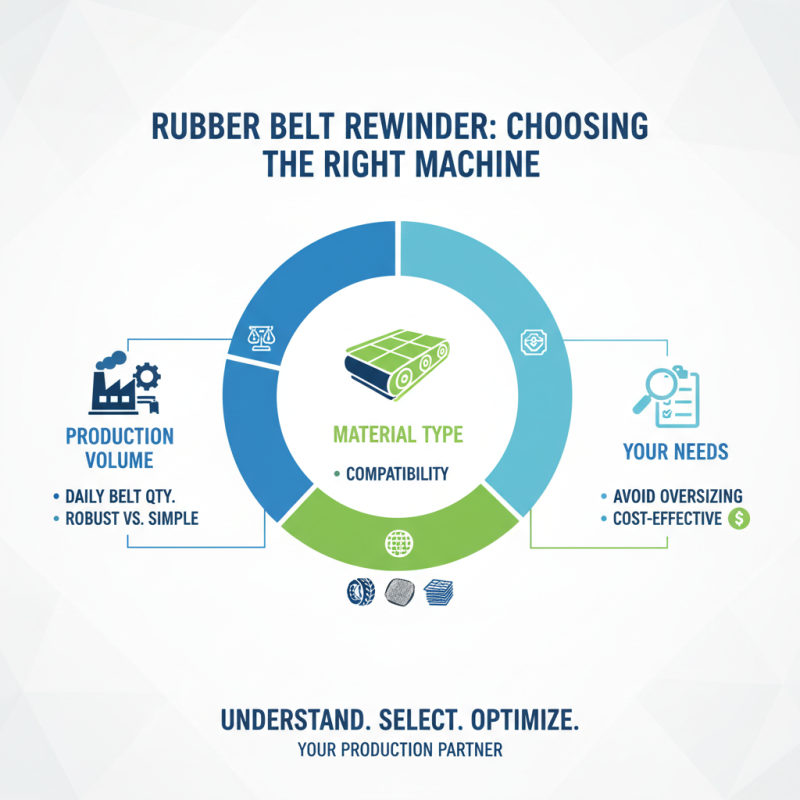

When selecting a rubber belt rewinder machine, understanding your production needs is crucial. Consider the volume of belts you'll rewind on a daily basis. High-demand environments may necessitate a machine with robust features and a larger capacity. However, it’s easy to overestimate your requirements. Sometimes, a simpler model suffices. Identify any specific materials you'll be working with as well. Different machines handle various types of rubber better than others.

The speed of operation is another factor that impacts productivity. Some machines offer multiple speed settings. This flexibility can be advantageous, but it could also lead to confusion. Users may not fully utilize all settings. Think about the training required for your staff as well. If your team isn't familiar with complex machines, a straightforward version might be more efficient. Remember to assess available space as well. A machine that fits perfectly in your workshop can greatly enhance workflow. Consider not just the current needs but also potential future requirements. Sometimes, a small investment in a more adaptable device pays off down the line.

When selecting a rubber belt rewinder machine, understanding the landscape of popular brands is crucial. According to industry reports, the global market for industrial rewinders is projected to grow at a CAGR of 5.2% through 2025. This growth indicates an increasing demand for efficient and reliable machines, yet the selection process remains challenging.

Many brands fall short in specific performance metrics. Some machines have inconsistent tension control, leading to improper winding. Reports highlight that over 30% of users indicate difficulties with setup and calibration. User feedback shows a preference for intuitive interfaces. A machine that allows for easy adjustments tends to outperform its competitors. The reliance on digital interfaces can also present challenges, especially for seasoned workers accustomed to analog controls.

Price is another contentious point. Data shows that cheaper options often compromise on quality. Evaluating long-term cost-effectiveness is essential. Investing in a higher-end machine can yield better productivity. Yet, some users feel overwhelmed with the plethora of choices available. It is clear from performance reviews that not all machines are created equal. Careful consideration and user experiences can aid in navigating these complex decisions effectively.

When choosing a rubber belt rewinder machine, budget considerations play a crucial role. You need to assess both upfront costs and long-term expenses. According to industry reports, companies often spend between $5,000 and $30,000 on such equipment. The large price range reflects the machine's capabilities and features. Cheaper models might lack the advanced technology or durability that higher-priced machines offer.

Maintenance costs are another key factor. Some machines require frequent servicing. Industry data suggests that maintenance can add up to 15% of the initial purchase price annually. If you opt for a low-cost machine, anticipate higher maintenance needs. This could ultimately offset any initial savings. Keep in mind that investing in reliable machinery may ensure less downtime.

Power consumption is often overlooked. Newer models are designed for energy efficiency. An efficient machine can reduce energy bills by up to 20% annually. This far outweighs any short-term savings from a cheaper machine that consumes more energy. Review the technical specifications carefully to ensure you're making a sound financial decision.

| Feature | Budget Option | Mid-Range Option | Premium Option |

|---|---|---|---|

| Max. Belt Width | 300 mm | 600 mm | 1000 mm |

| Motor Power | 1 HP | 2 HP | 5 HP |

| Speed | 0-10 m/min | 0-20 m/min | 0-30 m/min |

| Weight | 50 kg | 100 kg | 200 kg |

| Price Range | $1,000 - $2,000 | $2,500 - $5,000 | $6,000 - $10,000 |