Choosing the right High Speed Air Drill can significantly impact the efficiency and outcome of your projects. Whether you're a seasoned professional or a DIY enthusiast, understanding the features and specifications that make an air drill suitable for your specific needs is crucial. In this guide, we will explore essential tips to help you navigate the market of High Speed Air Drills, allowing you to make an informed decision.

From evaluating drill speed and torque to considering the tool's ergonomics and design, each factor plays a vital role in achieving optimal performance. By following this comprehensive outline, you’ll gain valuable insights into selecting the ideal High Speed Air Drill that aligns perfectly with your project requirements, ultimately enhancing your productivity and results.

When selecting a high-speed air drill for your project needs, there are several crucial factors to consider. Firstly, assess the drill's horsepower and RPM (revolutions per minute) specifications. These metrics directly influence the tool's performance capabilities. A drill with higher RPM is typically more efficient for tasks requiring precision and speed, such as metalworking or detailed woodworking. Additionally, ensure that the horsepower aligns with the material you plan to drill, as harder substances necessitate more power.

Another important aspect to evaluate is the ergonomics and weight of the air drill. A lightweight drill with an ergonomic design can enhance user comfort, especially during extended use. Take note of the grip and balance of the drill, as these features contribute to overall control and reduce fatigue. Furthermore, check the size and compatibility of the drill bits with various attachments, as this will impact your versatility and the types of projects you can undertake. By meticulously considering these factors, you can select a high-speed air drill that optimizes performance for your specific project requirements.

When selecting a high-speed air drill, understanding air pressure and flow rate specifications is crucial for achieving optimal performance in your projects. Air pressure is typically measured in pounds per square inch (PSI) and significantly influences the drill’s power. Higher PSI levels generally equate to increased torque and speed, allowing the drill to perform efficiently on tougher materials. However, it's essential to match the air pressure with the drill manufacturer's recommendations to avoid potential damage or decreased longevity of the tool.

When selecting a high-speed air drill, understanding air pressure and flow rate specifications is crucial for achieving optimal performance in your projects. Air pressure is typically measured in pounds per square inch (PSI) and significantly influences the drill’s power. Higher PSI levels generally equate to increased torque and speed, allowing the drill to perform efficiently on tougher materials. However, it's essential to match the air pressure with the drill manufacturer's recommendations to avoid potential damage or decreased longevity of the tool.

In tandem with air pressure, the flow rate, measured in cubic feet per minute (CFM), is another critical specification. The flow rate indicates the volume of air that the drill can utilize, directly impacting its operational efficiency. A drill with a higher CFM rating will sustain consistent performance, particularly during prolonged use. When selecting a drill, consider both the required PSI and CFM for your specific tasks to ensure that you achieve the best results and maintain the tool’s durability throughout your projects. Proper attention to these specifications will enhance performance and help prevent operational hiccups.

When selecting a high-speed air drill, evaluating the different motor types is crucial for achieving optimal performance tailored to your projects. The primary motor types found in air drills are vane, rotary, and piston motors. Vane motors are known for their lightweight design and smooth operation, making them ideal for precision tasks. They are excellent for applications that require agility and control, such as assembly work or delicate repairs.

On the other hand, rotary motors provide higher torque and are better suited for heavy-duty applications. They excel in tasks that involve drilling through tough materials or demanding continuous operation. If your projects frequently require durability and power, a rotary motor might be your best option. Finally, piston motors, while less common in air drills, offer substantial force and can be highly efficient for specific industrial tasks. Understanding the strengths and weaknesses of each motor type will help you determine the best high-speed air drill for your specific needs and ensure that your projects are completed efficiently and effectively.

| Motor Type | Max RPM | Torque (Nm) | Air Consumption (CFM) | Weight (lbs) | Best Use Case |

|---|---|---|---|---|---|

| Piston Motor | 40,000 | 1.5 | 5 | 2.3 | Precision drilling |

| Vane Motor | 30,000 | 2.0 | 6 | 2.5 | General purpose |

| Gear Motor | 25,000 | 3.0 | 8 | 3.0 | Heavy-duty applications |

| Electronically Controlled Motor | 50,000 | 1.0 | 4 | 2.0 | High precision tasks |

When selecting a high speed air drill, one crucial aspect to consider is the construction materials used in its design. The choice of materials not only influences the tool's durability but also impacts its overall weight, which is essential for user comfort during prolonged use. Common materials found in air drills include aluminum, magnesium, and various reinforced plastics. Aluminum, for instance, offers a good balance between strength and weight, making it a popular choice for manufacturers seeking to provide a lightweight yet robust tool.

Additionally, understanding how different materials affect vibration and heat resistance can enhance performance and longevity. For instance, magnesium alloys, while lightweight, can help in dissipating heat more effectively during operation, reducing wear and tear. On the other hand, reinforced plastics may offer superior resistance to corrosion, which is vital for tools exposed to harsh working conditions. Evaluating these factors will significantly aid in choosing a high speed air drill that not only meets performance standards but also ensures ease of handling and long-term reliability.

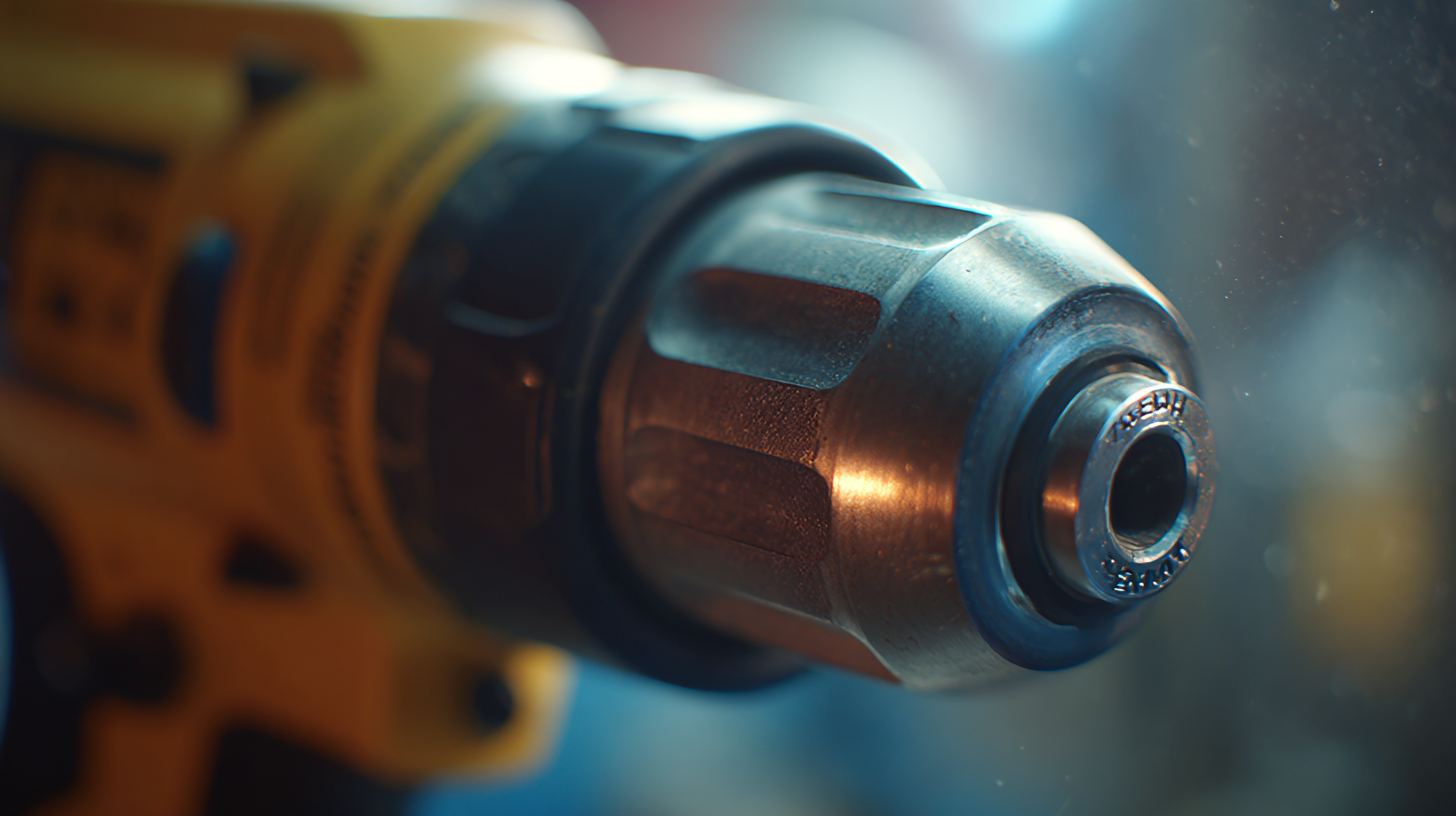

When selecting a high-speed air drill for optimal performance, understanding the significance of chuck size and its compatibility is crucial. The chuck is the part of the drill that holds the bit securely in place, and its size directly impacts the range of attachments you can use. Generally, most high-speed air drills feature chucks that are either 1/4 inch or 3/8 inch in size. If your projects require a variety of bit sizes, it is essential to choose a drill with a chuck that can accommodate larger bits, ensuring versatility across different applications.

Moreover, compatibility extends beyond just chuck size. You must also consider the types of bits and accessories available for your chosen drill. Some drills may have limitations in compatibility with certain bit styles, which can hinder performance and efficiency in specialized tasks. Therefore, before making a purchase, verify that the high-speed air drill can work seamlessly with the bits and attachments you plan to use. This attention to detail ensures that you maximize the drill’s capabilities, allowing for smoother operation and enhanced productivity in your projects.