When it comes to optimizing production efficiency in the leather and strap manufacturing industry, choosing the right Belt Strap Cutting Machine is crucial for meeting business needs. According to a report by Research and Markets, the global market for cutting machinery is expected to grow at a CAGR of 5.2% from 2021 to 2026, driven by increasing demand for precision and quality in manufacturing processes. Furthermore, a study by MarketWatch indicates that advanced cutting machines not only streamline operations but also significantly reduce waste, thus enhancing profitability. With various types of Belt Strap Cutting Machines available, businesses must evaluate their specific operational requirements, material compatibility, and production volume to make an informed decision. Selecting the appropriate machinery can lead to improved product quality, greater operational efficiency, and ultimately, a stronger competitive edge in the marketplace.

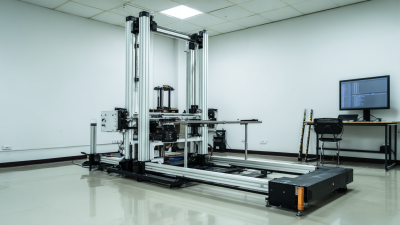

When choosing the right belt strap cutting machine for your business, it's essential to understand the different types available in the market. Belt strap cutting machines vary in functionality, precision, and intended use, catering to diverse production needs. Some machines are designed for heavy-duty operations, offering robust cutting capabilities for thicker materials, while others are more suited for delicate, intricate designs that require precision. Businesses should evaluate the materials they commonly use and the required production volume to determine which machine best fits their needs.

When choosing the right belt strap cutting machine for your business, it's essential to understand the different types available in the market. Belt strap cutting machines vary in functionality, precision, and intended use, catering to diverse production needs. Some machines are designed for heavy-duty operations, offering robust cutting capabilities for thicker materials, while others are more suited for delicate, intricate designs that require precision. Businesses should evaluate the materials they commonly use and the required production volume to determine which machine best fits their needs.

Additionally, features like automatic feeding systems, cutting speeds, and ease of operation play a significant role in machine selection. Advanced models may provide automated settings that optimize the cutting process and enhance productivity, making them ideal for high-demand environments. On the other hand, simpler machines may be more suitable for smaller businesses with occasional production needs. Ultimately, understanding these differences will help businesses make an informed decision and invest in a cutting machine that aligns with their operational goals.

When selecting a belt strap cutting machine for your business needs, evaluating production capacity and efficiency is crucial. According to a report from the Manufacturing Institute, over 80% of manufacturing companies face challenges related to production efficiency. A high-capacity machine can significantly enhance your output, ensuring you meet customer demand without compromising on quality. For instance, machines with a cutting speed of over 60 meters per minute can increase production by up to 30% compared to standard models.

Tips: Before making your decision, analyze your current production volume and projected growth. Choose a machine that not only accommodates your present needs but also supports scalability. Additionally, consider machines with programmable features that enable you to adjust settings for different belt sizes and materials, which can greatly enhance overall efficiency.

Investing in a machine with advanced features such as automatic feeding systems can further boost your operational efficiency. A study by the National Association of Manufacturers highlighted that organizations implementing automated solutions saw a 20% reduction in labor costs and improved production timelines. Therefore, prioritize machines that combine high production capacity with innovative technology to maximize your manufacturing efficiency.

When selecting a belt strap cutting machine, assessing material compatibility is critical for ensuring optimal performance. Different materials—such as leather, synthetic fibers, and textiles—each require specific cutting techniques and machinery features. According to a recent industry report by Smith & Associates, leather and synthetic straps demand precise cutting blades that can withstand their unique densities, while textiles may require machines that excel in speed and versatility. This compatibility not only affects the cutting quality but also the machine's longevity and maintenance costs.

Moreover, the choice of machine also influences production efficiency. The same report indicated that businesses using machines tailored for their specific materials had a 25% increase in output and a 15% reduction in material waste compared to those using general-purpose cutting machines. For example, belt strap cutting machines equipped with advanced sensors can adapt their cutting parameters based on the detected material thickness, promoting more consistent results and minimizing downtimes. Evaluating these material-specific features will help businesses maximize their operational efficiency and meet customer demands effectively.

When selecting the right belt strap cutting machine for your business, it is essential to focus on key features that can significantly enhance production efficiency and product quality. Firstly, consider the machine's cutting capabilities, including the type of cuts it can perform—whether straight, angled, or intricate shapes. A versatile cutting machine allows for greater design flexibility, enabling you to cater to various customer specifications and market demands.

Another crucial feature to look for is the machine's automation level. Advanced machines with automatic feeding and cutting systems can reduce labor costs and minimize human error. Additionally, seek a machine that offers easy adjustment settings for different belt sizes and thicknesses, as this flexibility can streamline your workflow. Furthermore, investing in a model with a robust build and high-quality materials ensures longevity, reducing downtime and maintenance costs over time. By prioritizing these features, you can make a more informed decision that aligns with your business needs.

When selecting a belt strap cutting machine, understanding the cost versus benefits is essential for making a smart investment decision. According to a recent industry report from Technavio, the global leather goods market is projected to grow at a CAGR of 6.2% from 2021 to 2025. This growth indicates that investing in high-quality machinery can significantly enhance production efficiency and product quality. Businesses need to analyze their production requirements, operational costs, and potential return on investment when choosing a cutting machine.

Tip 1: Conduct a cost analysis by estimating the machine's purchase price against its expected lifespan and maintenance costs. A durable machine may have a higher upfront cost but can save on repairs and replacements in the long run.

Additionally, consider the technology and features that come with the machine. Advanced cutting machines can often reduce waste material and increase precision, translating into better profit margins. A report by Grand View Research highlights that automated cutting processes can decrease labor costs by up to 30%.

Tip 2: Evaluate the machine's compatibility with your existing production line. Investing in equipment that seamlessly integrates into your current setup can minimize downtime and improve productivity. Investing wisely today will not only benefit your operations now but will position your business for future growth.