In today's manufacturing landscape, the efficiency of materials handling plays a crucial role. The right Conveyor Belt Slitter is essential for optimizing productivity and reducing waste. According to a recent report from the Conveyor Equipment Manufacturers Association, nearly 70% of production downtime is linked to conveyor system failures. Choosing the right slitter can prevent such disruptions.

Selecting a Conveyor Belt Slitter requires careful consideration of several factors. The type of material to be cut, the desired thickness, and the slitter's efficiency all influence the decision. Additionally, industry insights suggest that slitting accuracy can enhance product quality by up to 20%. However, many companies overlook maintenance requirements, leading to increased downtime and costs.

Navigating the options can be challenging. Some may settle for lower-cost alternatives, but this decision can result in higher long-term expenses. Ultimately, the right choice will depend on unique operational needs. A well-informed decision on a Conveyor Belt Slitter could mean the difference between smooth operations and costly setbacks.

When selecting a conveyor belt slitter, understanding the available types is crucial. Two common types are rotary slitters and shear slitters. Rotary slitters use circular blades and are efficient for cutting various materials. They operate at higher speeds, making them suitable for large-scale operations. Conversely, shear slitters employ a sliding blade technique. This is useful for specific materials that require precision.

Industry reports indicate that demand for conveyor belt slitters has been increasing. Research shows that the global market for these machines is projected to grow by over 5% annually through 2027. Users often undervalue the maintenance costs associated with each type. Paper mills and packaging sectors frequently prefer rotary slitters for their speed and efficiency.

However, shear slitters tend to be overlooked, despite their advantages in cutting thicker materials. Over time, this can result in operational inefficiencies. Users often find themselves reassessing their choices and reflecting on cost versus effectiveness. As you navigate this decision, consider the materials you'll be cutting and the production speed needed. Don’t forget to evaluate the long-term implications of your choice.

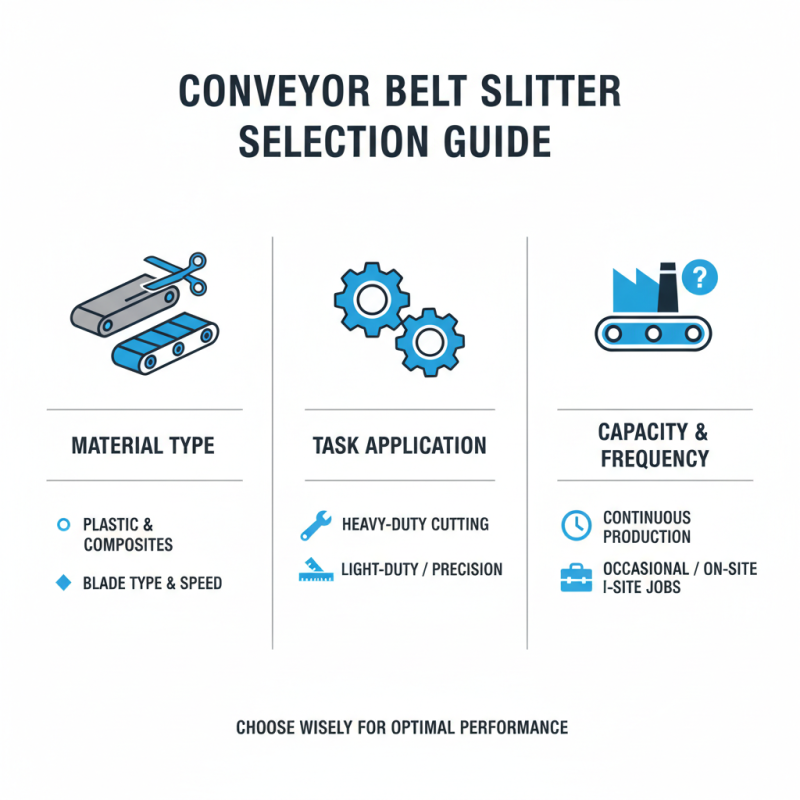

When selecting a conveyor belt slitter, several key factors come into play. The type of material you plan to cut is crucial. Different materials require various blade types and cutting speeds. For example, rubber belts may need a different approach compared to plastic ones. Consider what tasks you will perform. Will you need a machine for heavy-duty applications or lighter tasks? This will help narrow down your options.

Another vital aspect is the machine's speed and efficiency. A faster slitter may boost productivity, but it could also increase wear and tear. Assess the balance between speed and quality. In some cases, a slower, high-quality cut may be more beneficial. Check the blade sharpness and durability as well. Dull blades not only affect performance but can also lead to excess waste.

Tips: Consider the machine's ease of maintenance. Frequent upkeep can be a burden. Look for a design that simplifies this process. Additionally, ensure the safety features are adequate. Operators should feel secure while using the machine.

Lastly, gather feedback from users. Real-world experiences can highlight strengths and weaknesses. This insight will guide you to a more informed decision. Ultimately, reflecting on your specific needs will lead you to the right conveyor belt slitter.

Choosing a conveyor belt slitter tailored to your needs is essential for efficiency. Material compatibility plays a critical role in this decision. Different materials have unique properties. Rubber, fabric, and plastic belts each respond differently to slitting techniques. Understanding these nuances can lead to optimal performance.

When assessing material compatibility, consider factors like thickness and elasticity. Thicker materials may require specialized blades. Elastic materials often rebound, potentially leading to uneven cuts. This is a common pitfall. Conducting tests on sample materials can reveal issues early on. Not all slitting machines handle every material well, which can result in frustration and wasted resources.

Pay attention to the operational environment too. Dust, temperature, and humidity can affect performance. If your workspace is not carefully controlled, slitting may become inconsistent. Regular maintenance and adjustment are crucial. Reflect on past experiences when selecting a slitter. Review what worked and what didn’t. Learning from previous choices can improve future outcomes significantly.

| Material Type | Compatible Blade Type | Recommended Slitting Speed (m/min) | Thickness Range (mm) | Optimal Blade Diameter (mm) |

|---|---|---|---|---|

| PVC | High-Speed Steel | 50 | 1 - 5 | 75 |

| Polyurethane | Carbide | 40 | 2 - 6 | 60 |

| Rubber | Diamond Coated | 30 | 1 - 10 | 80 |

| Fabric Reinforced | Standard Steel | 60 | 3 - 8 | 70 |

| Polyethylene | Plastic Cutting Blade | 70 | 1 - 4 | 50 |

When selecting a conveyor belt slitter, understanding your production volume is crucial. If your operation requires high throughput, you need a robust machine. According to industry reports, slitter machines that can handle more than 1,000 meters of material per hour are optimal for large-scale operations. However, choosing a model that can adapt to variations might be beneficial for flexibility.

In lower production settings, a simpler slitter may suffice. Many small operations report processing around 200 to 500 meters per hour with satisfactory results. This can lead to significant cost savings. It is important to assess your specific volume needs before deciding. A mismatch can lead to inefficiencies.

Overlooking elements like the maintenance of the slitter can impact long-term productivity. The downtime required for maintenance can be substantial. Regular maintenance is necessary to prevent unexpected halts in production. Production volume is not just about output; it’s also about reliability and efficiency. Thus, selecting the right slitter is not only about current needs but future growth as well.

When choosing a conveyor belt slitter, safety features are paramount. Many industries rely on this equipment daily. According to industry reports, over 70% of workplace accidents involve machinery. This statistic highlights the importance of compliance with safety standards. Ensure the slitter you consider has emergency stop buttons, guards, and clear safety warnings. Compliance with ISO and OSHA standards should be a priority.

Evaluating the construction of the slitter is crucial. Look for robust materials that can withstand rigorous use. Poorly built equipment can lead to unexpected failures. Such failures often result in costly downtime. It's essential to assess the manufacturer's commitment to safety. Are safety audits a norm? Do they update their equipment according to new regulations? These questions matter.

Design features also enhance safety. Some slitters offer automatic blade shutoff or sensors that detect operator presence. These innovations significantly reduce risk. However, not every model incorporates advanced technology. It's essential to weigh the pros and cons carefully. Sometimes, older models might lack modern safety features but are more reliable. Balancing safety and functionality can be a challenge. Each operation must consider its unique needs.