The demand for high-quality leather products continues to rise. One essential tool for leather craftsmen is the Leather Belt Strap Cutting Machine. This machine revolutionizes the way leather belts are made. It allows for precision cuts, enhancing both quality and efficiency.

As we look ahead to 2026, choosing the right cutting machine remains a challenge. Not every machine lives up to expectations. Selecting one with durability and reliability is crucial. Factors such as blade sharpness and ease of use can greatly impact production.

Many machines may seem effective but have hidden flaws. Some may require frequent maintenance, while others might not handle thicker leather well. Reflecting on these issues can lead to better choices. Craftsmanship is an art, and the right tools can make all the difference.

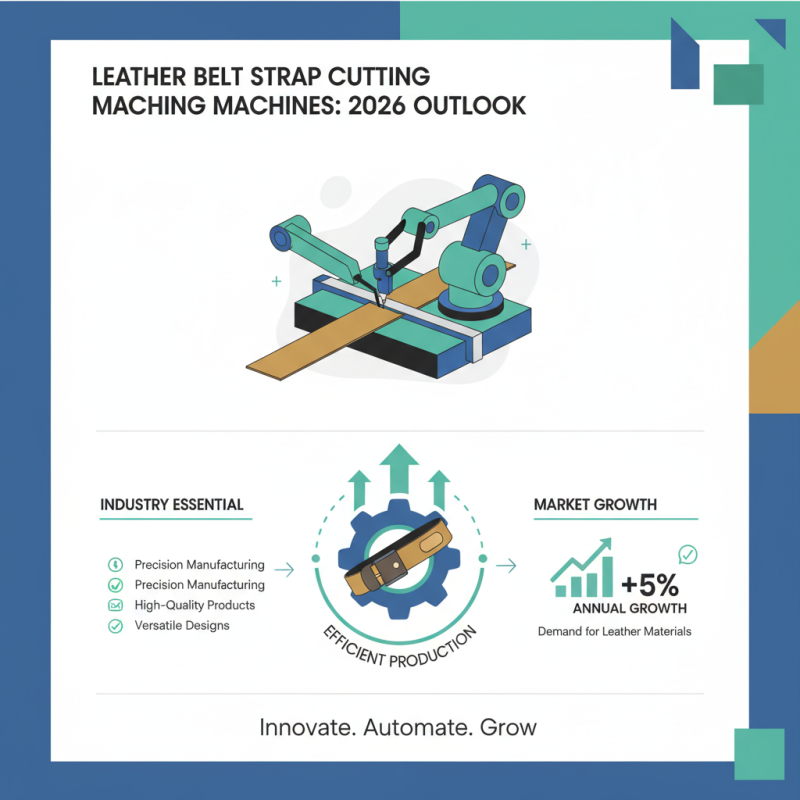

In 2026, leather belt strap cutting machines are becoming essential in various industries. These machines design and manufacture high-quality leather products. According to industry reports, the demand for leather materials is projected to grow by 5% annually. This growth pushes manufacturers to seek efficient cutting solutions.

Precision is crucial. An accurate cutting machine reduces waste and maximizes material use. Choosing the right machine can save costs. A minor error can create significant losses over time. Reports indicate that up to 10% of material is often wasted in manual cutting processes. Automating these processes improves efficiency and product quality while minimizing human error.

**Tips:** When selecting a cutting machine, consider its versatility. Machines that can handle different leather types offer better flexibility. Regular maintenance is necessary to ensure peak performance. A neglected machine may lead to inconsistent cuts and increased downtime. Always assess your production needs before purchasing. Balancing cost and functionalities is a challenge many face, yet it is vital for long-term success.

When selecting the best leather belt strap cutting machine, focus on precision and durability. A credible industry report indicates that machines with laser cutting technology provide up to 90% accuracy in cuts. This level of precision minimizes material waste. Inefficient machines often lead to overuse of resources and increased costs.

Speed is another critical factor. The average cutting speed should be around 600mm per second to keep up with production demands. However, some machines compromise speed for quality, resulting in rugged edges. Such imperfections may hinder the final product's appeal. Look for user reviews highlighting performance in busy environments.

Furthermore, consider maintenance requirements. A study suggests that machines requiring frequent upkeep lower productivity over time. Regular inconsistencies can disrupt workflow, affecting part quality. Users must find a balance between technology and user-friendliness. Assessing these aspects ensures a well-rounded choice.

The leather belt strap cutting machine market is evolving rapidly. In 2026, users seek efficiency and precision. A recent industry report highlights a 15% increase in demand for automated machines. Leather goods manufacturers prioritize high-quality cuts and minimal waste. This shift influences machine design significantly.

Top brands in the cutting machine sector focus on durable materials and user-friendly interfaces. Machines equipped with digital controls are gaining popularity. They allow precise adjustments for various leather thicknesses. The trend emphasizes sustainability. Several reports suggest manufacturers can reduce waste by up to 30% with advanced cutting technology.

Yet, challenges remain. Some users report difficulty in maintenance. Regular servicing may not be straightforward. A lack of proper training can lead to suboptimal use. Feedback from operators indicates the need for better instructional support. As the market grows, addressing these gaps will prove essential for long-term success.

| Model | Cutting Speed (m/min) | Max Cutting Thickness (mm) | Weight (kg) | Price ($) |

|---|---|---|---|---|

| Model A | 15 | 5 | 20 | 300 |

| Model B | 20 | 6 | 25 | 450 |

| Model C | 18 | 7 | 30 | 400 |

| Model D | 12 | 8 | 22 | 250 |

| Model E | 25 | 6 | 28 | 600 |

The cutting technology in leather processing has evolved significantly. In 2026, innovative features in leather belt strap cutting machines stand out. Precision is enhanced through advanced laser cutting methods. These methods reduce waste and increase accuracy. The results are cleaner edges and a professional finish.

Moreover, user-friendly interfaces are becoming standard. Many machines now offer touchscreens and programmable settings. These features allow for quick adjustments. This ease of use attracts both experienced craftsmen and beginners. However, some still struggle to fully utilize these advanced functionalities. Training is essential but often overlooked.

Automatic feeding systems are also noteworthy. They streamline the cutting process and minimize manual handling. Still, the reliability of these systems can vary. Issues like jamming or uneven feeding can occur. It reminds users to remain vigilant and adaptable, even with modern technology. As innovations continue, a balance between automation and skilled craftsmanship persists, posing a reflective challenge for the industry.

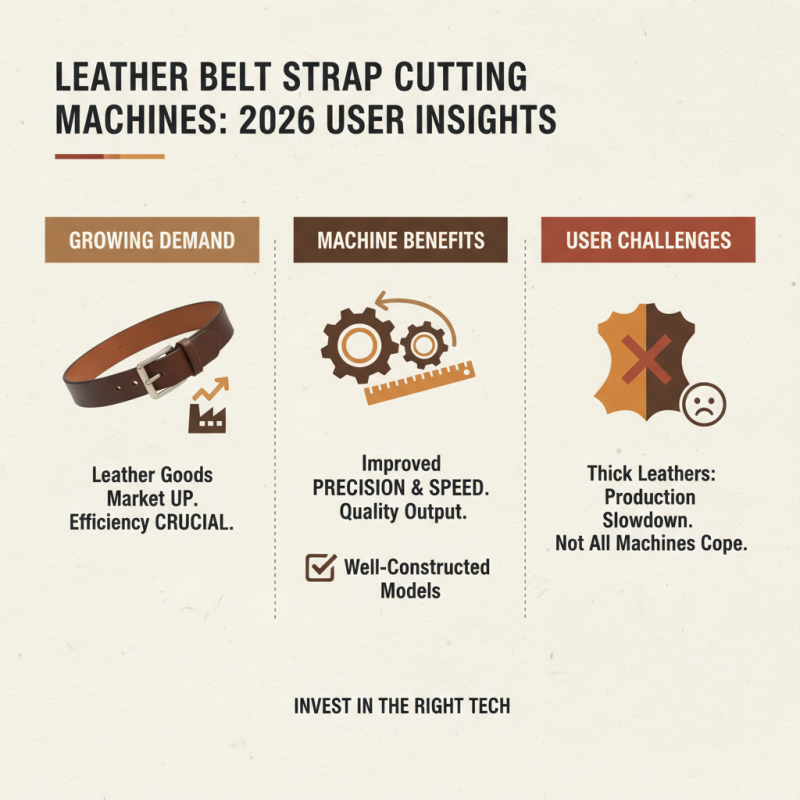

As the demand for leather goods grows, the right cutting machine becomes essential. In 2026, users have shared valuable insights on various leather belt strap cutting machines. A well-constructed machine can drastically improve efficiency and precision. Some users highlight that even the best models can struggle with thicker leathers. It creates frustration during production.

User reviews often point to critical features. Speed, blade quality, and ease of use are paramount. Some machines boast automatic settings. Yet, not all users find them user-friendly. Feedback suggests that manuals can be unclear, causing initial confusion. Many recommend taking time to understand the machine fully.

Comparisons reveal that durability is a mixed bag. Some machines last for years, while others have issues after a few months. Users stress the importance of maintenance to prolong lifespan. One user mentioned that minor adjustments can enhance cutting accuracy. Hence, investing in better materials and maintenance practices can make a big difference. These experiences offer a glimpse into the strengths and weaknesses of current machines in the market.